Understanding Robotic Vision: Why It Is Essential for Modern Automation Processes

Robotic vision represents a substantial development in automation technology. It allows machines to assess visual data, boosting their capability to perform jobs with accuracy. This capability is changing markets by improving performance and reducing human mistake. Nevertheless, the integration of robotic vision likewise postures obstacles. Comprehending its implications is crucial for companies aiming to stay affordable. What factors influence its adoption, and how can business utilize this technology properly?

The Fundamentals of Robotic Vision Innovation

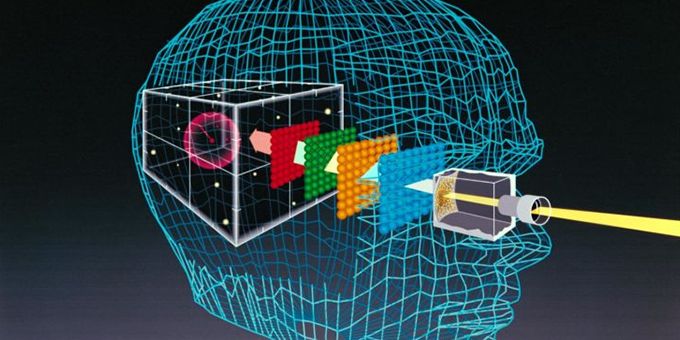

Robotic vision technology works as the backbone of automation in different industries, enabling devices to view and analyze their environments. This technology integrates sophisticated imaging systems, such as electronic cameras and sensors, with innovative algorithms that process visual information. By recording pictures and evaluating them in real-time, robot vision allows machines to recognize things, assess their positions, and make informed decisions based upon visual input.Key elements of robot vision include picture handling strategies, equipment knowing designs, and depth assumption systems, which work collectively to enhance a robotic's understanding of its atmosphere. Calibration and environmental versatility are additionally critical, guaranteeing that systems can operate efficiently under varied conditions. This fundamental modern technology not just boosts functional performance yet likewise boosts security by enabling robots to browse complicated settings while decreasing mistakes and mishaps. As industries continue to progress, the significance of robust robot vision innovation stays vital in driving advancement and productivity.

Secret Applications of Robotic Vision in Industry

The application of robot vision modern technology spans a wide range of sectors, greatly boosting operational capabilities and performance. In production, robotic vision systems allow accurate examination and quality control, making certain products meet stringent criteria. In the automotive field, these systems assist in jobs such as element setting up and flaw detection, simplifying manufacturing lines.In logistics, robot vision plays an important role in automated product handling, enabling robots to browse complex settings and accurately recognize items for arranging and loading. The food sector utilizes robotic vision for sorting and packaging, ensuring uniformity and conformity with health and wellness regulations.Additionally, in medical care, robot vision help in procedures and diagnostics, supplying boosted accuracy and minimizing threats. In general, the varied applications of robot vision technology add to increased efficiency and innovation across numerous sectors, showing its significance in modern-day commercial processes.

Advantages of Implementing Robotic Vision Solutions

Applying robot vision systems uses countless advantages that considerably boost functional efficiency and accuracy across different sectors. These systems make it possible for makers to regard and interpret their surroundings, bring about enhanced decision-making procedures. Boosted accuracy in jobs such as quality assurance and sorting lessens human mistake, guaranteeing constant item standards.Moreover, robot vision systems can operate constantly, boosting performance while reducing labor costs. They are capable of executing elaborate jobs at high speeds, permitting for faster manufacturing cycles. The integration of innovative imaging technologies facilitates real-time information collection, empowering firms to analyze efficiency metrics and simplify operations.Additionally, the versatility of robotic vision systems allows them to be employed in varied applications, from automobile assembly lines to food packaging. By offering reliable and precise automation solutions, these systems help businesses keep an affordable side in an increasingly automated marketplace, highlighting their essential role in modern-day production atmospheres.

Challenges and Limitations of Robotic Vision

While robotic vision systems supply significant advantages, they also encounter a number of difficulties and restrictions that can hinder their performance. One primary obstacle is the variability in lights conditions, which can substantially impact photo top quality and cause false impression of visual information. Additionally, the intricacy of real-world settings, filled up with vibrant things and differing appearances, poses troubles in things recognition and tracking.Another limitation is the reliance on premium sensors and progressed algorithms, which can be pricey and require extensive calibration. In addition, robotic vision systems might deal with depth understanding and three-dimensional understanding, specifically in cluttered settings. optical measurement system.Finally, the integration of robot vision with existing automation systems can be complicated, needing detailed training and shows. These challenges underscore the significance of continuous r & d to enhance the capabilities and reliability of robot vision technologies in different applications

The Future of Robotic Vision in Automation

The future of robotic vision in automation promises substantial advancements in boosted object acknowledgment and boosted navigating systems. As modern technology advances, these technologies will certainly make it possible for robotics to connect extra successfully with their environments and do intricate jobs with better precision. This progression is expected to redefine functional capabilities across various markets.

Enhanced Item Recognition

Enhanced things recognition stands at the leading edge of innovations in robot vision, transforming exactly how automation systems regard and interact with their settings. This modern technology allows robotics to identify and categorize a substantial range of things with amazing precision, helping with a lot more efficient procedures across different sectors. Utilizing deep learning algorithms and advanced imaging strategies, systems can identify items in dynamic settings, adapting to adjustments in lighting, angles, and occlusions. As a result, improved things recognition not only simplifies processes such as sorting, choosing, and quality assurance go to this site however additionally reduces errors and boosts efficiency. The continuous advancement in this area promises to additionally integrate robotics right into everyday jobs, significantly boosting functional efficiency and leading the way for smarter automation services.

Improved Navigating Equipments

Developments in navigation systems are positioned to reinvent robot vision in automation, making it possible for robotics to go across intricate settings with extraordinary precision. By incorporating sophisticated sensors, man-made intelligence, and equipment knowing algorithms, these systems promote real-time mapping and localization. This permits robots to adapt to dynamic environments, avoiding barriers and maximizing courses effectively. Enhanced navigating capabilities encourage robotics to carry out jobs in numerous setups, from warehouses to medical care centers, improving productivity and safety. Additionally, the continual development of these technologies assures to minimize functional prices by minimizing errors and downtime. As the need for automation increases, boosted navigation systems will certainly play an essential role fit the future of robotic vision, ensuring seamless combination right into everyday operations.

Incorporating Robotic Vision With Various Other Technologies

Integrating robot vision with other modern technologies significantly enhances automation capacities across different industries. By incorporating innovative imaging systems with expert system, device learning, and Internet of Points (IoT) connection, organizations can attain unmatched performance and accuracy in their procedures. For instance, robotic vision can be made use of together with machine discovering formulas to improve item acknowledgment and decision-making processes, allowing robotics to adjust to dynamic environments.Additionally, when integrated with IoT tools, robotic vision systems can promote real-time data analysis and comments loopholes, optimizing operations and reducing downtime. This harmony permits for specific quality assurance and anticipating upkeep, inevitably decreasing operational costs. Integration with collaborative robots (cobots) enhances human-robot interaction, making automation safer and more effective in environments where human oversight is necessary. The convergence of robot vision with corresponding innovations is pivotal for driving development and efficiency in modern-day automation procedures.

Often Asked Concerns

How Does Robotic Vision Differ From Human Vision?

What Sorts of Cameras Are Utilized in Robotic Vision?

Various types of electronic cameras are utilized in robotic vision, including CCD, CMOS, and depth navigate to this site cameras. optical measurement system. These electronic cameras enable robots to view their setting, facilitating tasks such as object recognition, navigation, and high quality inspection in automated systems

Can Robotic Vision Solutions Gain From Experience?

Robotic vision systems can undoubtedly learn from experience. Via advanced algorithms and artificial intelligence techniques, they adapt and improve their visual recognition abilities, enhancing their efficiency in numerous tasks in time as they process brand-new information.

Exactly How Do Illumination Conditions Influence Robotic Vision Efficiency?

Lighting conditions significantly impact robotic vision efficiency by affecting picture comparison, color accuracy, and things detection capabilities. Not enough or extreme light can result in misinterpretation of continue reading this aesthetic information, influencing the general efficiency of robotic systems.

Are There Safety And Security Interest In Making Use Of Robotic Vision?

Security issues with robotic vision include possible false impressions of environments, resulting in accidents. Insufficient sensor calibration or environmental changes can worsen these dangers, necessitating strenuous testing and adherence to safety requirements for reliable implementation.